Precision since 1929

As a reliable partner in the field of mechanical engineering/machining, tool design/construction and jig manufacturing we offer you a comprehensive range of services.

We are active both as a service provider for a wide range of customers and as a manufacturer of our own products. We are characterized by innovation, the highest level of craftsmanship and absolute adherence to deadlines.

Thanks to decades of customer relationships, continuous training of our team and ongoing investments in our machining centers we are always at the cutting edge of technology (state of the art) and supply quality products made in Germany.

Our company headquarters are located in Pinneberg, Schleswig-Holstein, around 18 kilometers northwest of our former headquarters in Hamburg-Altona. The company was founded in Altona in 1929 by Wilhelm Rixen and produced on site until the move in 2014.

This brought several advantages. Not only were we able to build a modern production facility in Pinnenberg according to our wishes, but we also had the opportunity to expand our site. At the new address "Am Hafen 58", we have benefited from significantly improved loading and unloading options and a convenient location since the move. In addition, we have been able to recruit further excellently trained colleagues to join our core workforce.

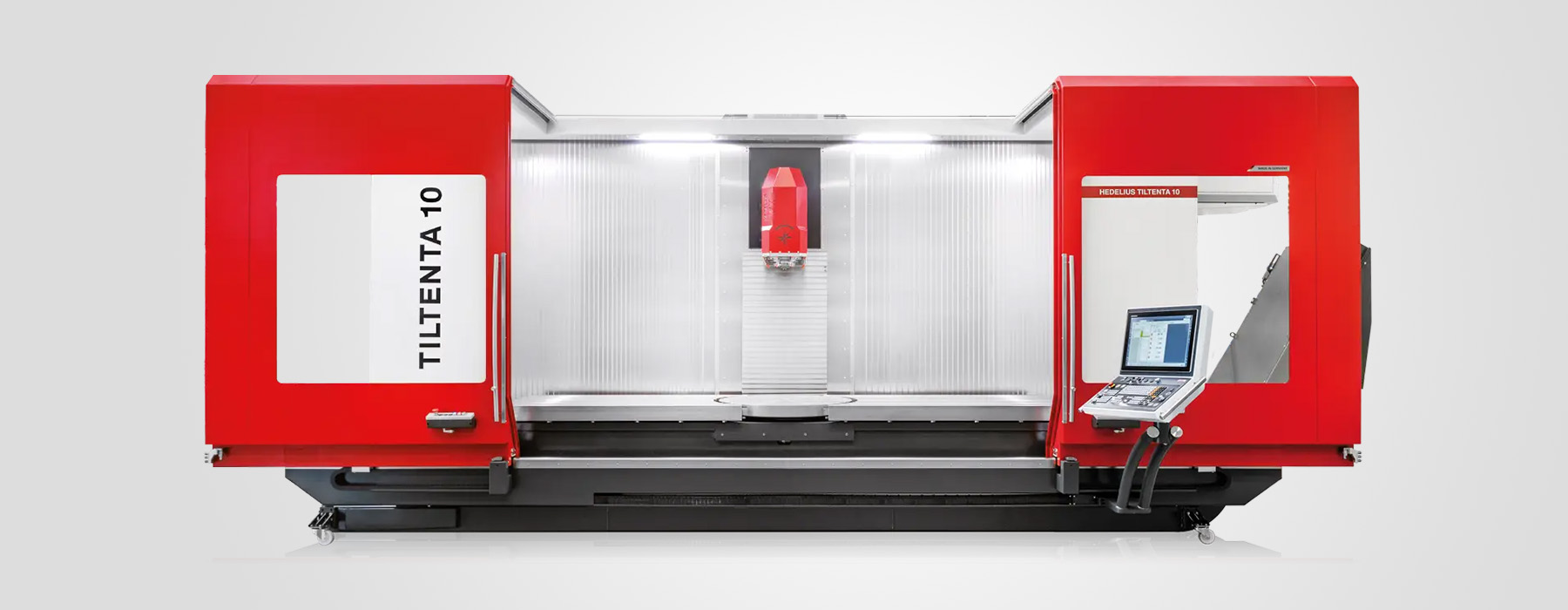

From spring 2026, the HEDELIUS TILTENTA 10 Magnum - 1R - 3600 will expand our machine park

We are investing in state-of-the-art manufacturing technology and will be expanding our machine park from spring 2026 with a HEDELIUS TILTENTA 10 Magnum - 1R - 3600 machining centre. The new machine is expected to be available from April/May 2026 and will significantly strengthen our production capacities in large-scale machining as well as in the manufacture of complex components.

The new TILTENTA 10 Magnum – 1R – 3600 delivers impressive travel ranges of 3600 x 1000 x 1000 mm (X/Y/Z), offering ideal conditions for machining large and demanding workpieces. Its integrated heavy-duty rotary table enables 5-sided and 5-axis machining of components weighing up to 2,200 kg, making the machine highly versatile – particularly in mechanical and plant engineering.

A technical highlight of the TILTENTA series is its infinitely adjustable main spindle, which allows flexible machining of cubic components as well as precise processing of long workpieces. The machine comes equipped as standard with an SK50 BIG PLUS spindle system, with an optional HSK A100 interface – ensuring maximum stability and excellent machining performance.

A generously sized tool magazine, combined with the ability to accommodate extra-long tools, enables the efficient execution of complex machining operations in a single set-up. This reduces the number of re-clamping processes required, thereby increasing precision and overall productivity.